"Sand Filter" Media - What Are The Options? (Sand, Glass, OC-1)

- energiseleisure

- Jan 8, 2021

- 8 min read

Updated: Feb 26, 2022

Sand has been used for water filtration (by humans, on purpose) for millennia so it's clear that it works effectively, relatively cheaply, and is generally in plentiful supply - it's also still the default filter media for the majority of swimming pools.

Sand is so synonymous with filtration that attempts to shift naming conventions towards "media filter" still haven't really caught on and people still refer to the choices as "cartridge filter" or "sand filter". Even pool engineers will make reference to "putting glass in the sand filter", so ingrained is the relationship with sand.

Before we get into comparing the four main types of filter media prevalent in the UK, though, let's address some options with a brief mention and then ignore them for a while:

Diatomaceous Earth (DE)

DE Filters are mostly a thing of the past for UK swimming pools. With quite specialised benefits that have been taken up by other, easier to use types of filter media, they just aren't seen to be worth the additional work and maintenance compared to other types of filter media except in some legacy systems and for specific circumstances.

Zeoclere (Mineral)

Zeoclere is very good at what it does, comes with some niche benefits, and is NSF-61 and NSF-50 certified. The downside is that its cost outweighs the benefits for most typical pool users. Zeoclere is a product that we are happy to use and even to recommend if the circumstances are correct

Polymer Fibre/Fibre Balls

A relatively new addition to the range of options, and one that Energise Leisure Ltd is cautiously optimistic about; but we are waiting to see if progress is made on relevant certification and if potential regulation changes will have any effect. One manufacturer we've looked into has a vast range of testing certificates and supporting documentation suggesting a highly effective product, but none of them yet appear to include "ISO", "NSF", or similar - only Oeko-Tex Standard 100, which is a textile certification. The benefits look promising (ease of use, filtration to 8 microns, filter efficiency, biocidal silver) so if anyone is interested and wants to try it then let us know, but we aren't comfortable recommending it at this stage with limited certification and real-world case studies.

On to the main event...

Filter Sand

As mentioned above: sand works. It's worked for thousands of years and remains the champion of swimming pool filter media (for now). Usually used in 16/30 grade, but occasionally mixed with larger grades forming a base layer, sand filters pollutants out of water down to approximately 5 microns (80% removal per pass), but upon first installation this is usually higher. Smaller particles may be removed, but at far reduced rates and filtration efficiency.

The key drawbacks of sand compared to others generally lie in longevity and efficiency. Sand is relatively dense and coarse, so requires a lot of water to backwash (clean) especially as it gets older, it potentially starts to compact in places, doesn't settle well to prevent channelling if you have flow inefficiency (which can actually be created by the compaction), potential for bacteria entrapment, and (from an engineer's perspective) is so darn heavy and difficult to shift when servicing a filter. The industry standard recommendation is a 5 year lifespan before replacement - beyond this you will gradually see degradation of water quality through increased cloudiness (and that's just what you can see). On the smallest of pools and filters these issues are generally less likely or less severe, but as you shift up to larger filters and heavier loads the problems can start to surface...

But why do these things matter if it's worked for so long? Well, all the required backwashing throws water down the drain, which needs to be replaced. Fresh water requires fresh heat and potentially additional chemicals for balancing. Factor all of that in and the money you might have saved with the cheaper option has gone down your drain not long after.

Also, 95% removal of 25 micron particles is becoming an ever weaker benchmark - and that's only during peak efficiency - so better media equals better water as well as lower long-term costs.

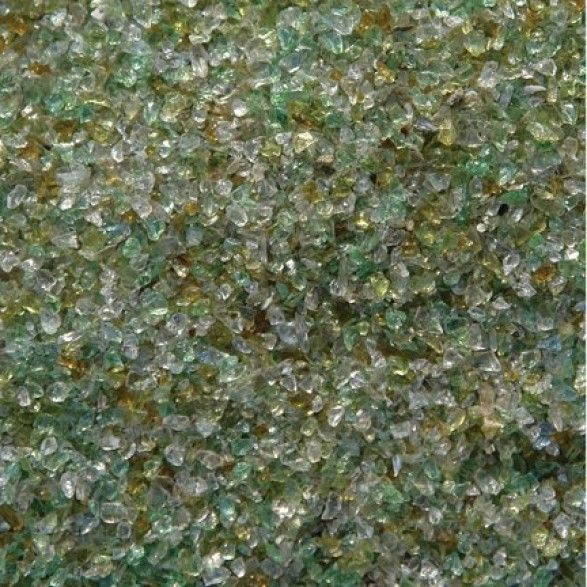

Recycled Glass

Also commonly referred to as "crushed glass", "eco glass", "EGFM", or simply "glass media" it is indeed made from recycled glass, but it is not "crushed" in the traditional sense. The production process involves using a shockwave to shatter the glass in such a way that it implodes to form sand-like, sharp-free granules. Some additional processing and screening gets you the final product which is 100% safe to handle:

Over a few weeks in 2009 approximately 1 tonne of media was spilled from a filter at the Wales National Pool; no cuts were reported and it was confirmed (in quite catastrophic fashion) that glass was no more dangerous than sand. We say "catastrophic", but the pool never had to close to the public.

It's important to note that PWTAG (the Pool Water Treatment Advisory Group" who produce the guidelines for commercial water treatment, support the use of glass for filtration that meets certain standards (ISO 9001, 14001, and 18001, BS EN 16713, or BS EN 12902, DWI certificate 31 and NSF 61 and NSF 50). This has led to uptake in numerous high-profile commercial installations and is also in widespread use in the domestic market.

The glass filter media used by Energise Leisure is certified to the three ISO standards given above as well as DWI 31, has a high purity with no crystalline free silica or heavy metal contaminants, and is 100% recycled from household recycling schemes.

Benefits over sand:

removes up to 30% more contaminants

reduced head loss/pressure build-up increasing efficiency

20% reduction in mass required compared to sand

often needing less brings the cost at least close to that of sand

reduced backwashing requirements = lower water loss (reduced chemical and heating costs)

reduced clumping and channelling

reduced bacterial build up due to fewer surface imperfections (reduced chemical usage and chloramine production)

doesn't degrade as rapidly so has a longer life expectancy

no alterations are required to existing filters to convert from sand

As a cost-effective, superior alternative, Glass filter media is currently the default recommendation from Energise Leisure for the majority of our customers.

Glass Beads

Also referred to as "glass pearl" or "virgin glass", glass beads are manufactured from new glass so don't have quite the same eco credentials as standard glass media; they do, however, come with a lot of increased benefits.

They also come with a sizeable increased cost which we think means they may eventually lose the battle.

A key UK supplier of this product is Waterco, a globally recognised and respected manufacturer of filtration systems. They had it tested against Australian drinking water guidelines (they are an Australian company, after all) and the product was found to be well within the parameters set. It has also been performance tested by TUV.

As they are hard, glass balls, there is zero compaction and they are incredibly mobile - you can very safely and easily push your hand down into them, remove it, and the glass will mostly resettle. It's this mobility and lack of friction that is at the centre of many of this product's benefits.

Benefits over sand:

smaller particles = densely packed bed and increased pollutant removal

efficiently and effectively removes particles down to 3microns

20% less backwash water required than sand due to flow efficiency of spherical shape

reduced backwashing and water loss = reduced chemical and heating costs

reduced head loss/pressure build-up increasing efficiency

no clumping

reduced bacterial build up due to smooth surface (reduced chemical usage and chloramine production)

doesn't degrade as rapidly so has a longer life expectancy

no alterations are required to existing filters to convert from sand

Glass beads are incredibly superior to sand and we have seen them used in many commercial and domestic pools with great results in water clarity and running cost reductions. Although expensive, water, heating, and chemical cost reductions mean there is a cost-clawback once installed, but the larger the installation the better the effect of this is (the alternative view is that the initial cost implication is far less on smaller installations).

OC-1 Filter Media

No, that image isn't magnified, those holes aren't microscopic. At first glance it's easy to wonder "how does anything get trapped in those massive holes?", but understanding OC-1 requires stepping outside of the typically understood model of filtration.

Sand and glass both work via a process of entrapment - particles simply can't squeeze between the grains.

OC-1 on the other hand removes particles through settlement - pollutant material simply drops out of the water. As water moves through the different beads, it is constantly changing direction and when water turns a corner its velocity changes - water moves slower on the inside of the bend and faster on the outside. Where the water moves more slowly, particles are simply dropped out of suspension because the flow isn't fast enough to overcome gravity.

The easiest comparison to draw is silt and pebbles being deposited by a meandering river. This process is self-improving, because the effect is greater once deposits have begun to form. Even better is that there is practically zero loss of flow efficiency because of all the space that the water still has available to travel through - better for your turnover, easier on your pump, and less backwashing required because you don't get that same pressure increase as with sand and glass.

OC-1 is far lighter and therefore easier to install (and eventually remove), and despite being plastic has eco credentials due to being manufactured in the UK and fully recyclable at the end of its life. It has been tested in accordance with BS EN 16713 by IFTS and found to remove 99% of 20 micron particles each pass (sand is between 90-95%), 81% of 10 micron particles, and 11% of 1 micron particles each pass. It performed so well in tests that time limits were reached before the filter media reached its operational limit.

On the topic of those operational limits, over the course of 8 hours with a total of 154g pollutant powder being added, there was almost no overall change in differential pressure (i.e. the filter didn't clog) - the test was abandoned at that point. In the same test, sand clogged after 2 hours/45g of test powder.

Not only does it greatly outperform sand for pollutant removal and capacity, there are options for implementing the flow efficiency benefit - you can turn your pump down using an inverter to save energy, or run the pump exactly the same producing increased flow (increased turnover rate, more filtration cycles in the same period of time, more pollutants removed; OR a domestic pool on a time switch to achieve x many turnovers per day could run the pump for less time). Backwashing is also a lot easier - large systems that use two pumps could potentially backwash with just one, large and small systems can backwash less frequently (staying mindful of TDS and cyanuric acid levels), and for less time using less water (back to reduced heating and chemical costs again!).

So what are the disadvantage of OC-1?

up front cost of the media itself

existing filters require additional parts and adaptation for conversion

there have been rare instances water quality problems post-installation*

Cost is easily overcome by the savings - pay back on some installs has been as little as 6 months. Water quality problems however... we can explain:

*All problems experienced that we are aware of have been on existing pools being converted from other filter media. The problems were found not to be the fault of the OC-1, but either poor installation (it wasn't us!), or existing problems with the hydraulics or treatment/other management of the pool water that were masked (ironically) by the entrapment method of filtration.

As such, despite all the great aspects of OC-1, Energise Leisure is cautious about defaulting to OC-1 for all installations. A lot of customers might not be able or willing to pay the up front cost, but customers interested in OC-1 will have their pool assessed to check if it is suitable.

To make an enquiry or to ask more questions, call us on 0333 577 9692 or email enquiries@energiseleisure.co.uk.

Commentaires